The verification service of the operating condition of a machine or installation, made by DMC, It helps identify whether a machine or group of machines is functioning properly.

The DMC performs verification of the operating condition with the following technologies:

Verification of operating condition, performed by the services of DMC, It can occur in different circumstances:

- Before or after a stoppage for maintenance;

- At the start of a new machine;

- If there is suspicion of abnormal behavior.

Condition Control with Troubleshooting and Problem

Table 1- Condition Control Method Comparison with the Malfunctions and Troubleshooting

| Trend Monitoring | Checking the condition | fault diagnosis and problems | |

| Height measures | Readings taken at regular intervals with the machine in service | Readings once with the machine in service | When the problem occurs, or after the occurrence of the fault |

| Qualitative measures | Qualified operators who are near the machine may make a subjective trend | Typical activity when a technician checks a service machine | When a machine for inspection of components may indicate the cause of the problem |

| Quantitative measures | Registration and interpretation of the results of regular measurements gives a warning period compared to machine problems | The numerical values allow comparison with standards or other similar machines knowing the condition of the equipment | Inspection results can be analyzed in considerable detail by providing information on the possible causes of the problem |

Condition Control

- Check the condition takes place by measuring a parameter, at a certain time, thereby inferring the state machine.

- To be effective, the measurement must be accurate, measured values must also be known limits not to be exceeded for more than a certain number of operating hours.

- The limits, to be established, require a wide previous experience with the particular type of machine in question.

- A check of the condition is, therefore, less flexible than the trend-following, especially with regard to the warning time before failure.

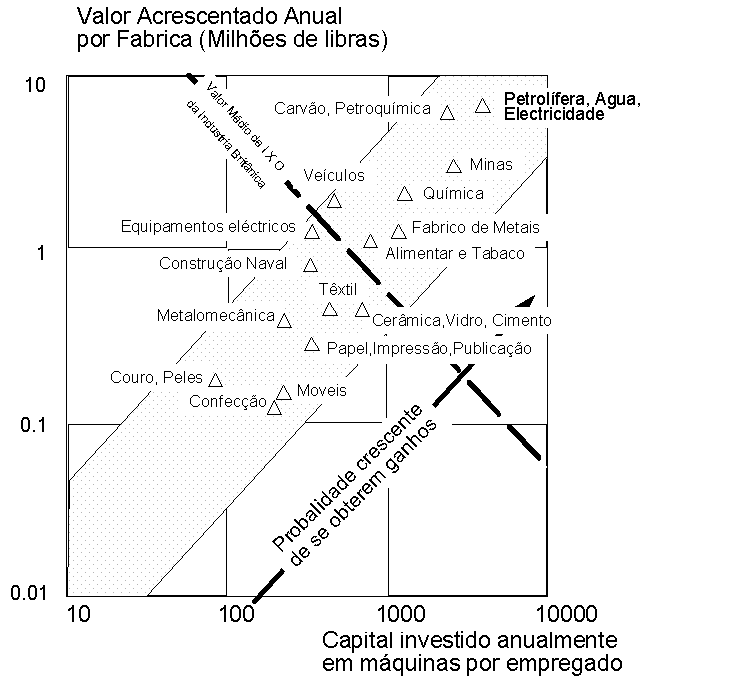

The figure shows the results of a study carried out in Great Britain, in 1978 on which industrial sectors that suit the application of predictive maintenance.