False positive and negative in Fasit

This article explains the concepts of false positive and negative in the Fasit.

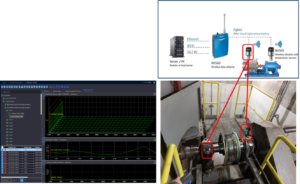

1 – O sistema fasit da adash

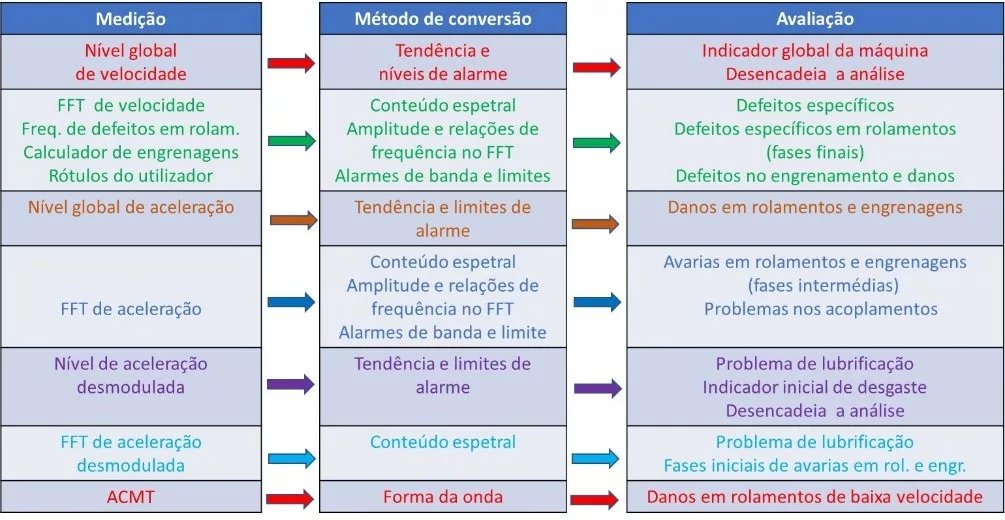

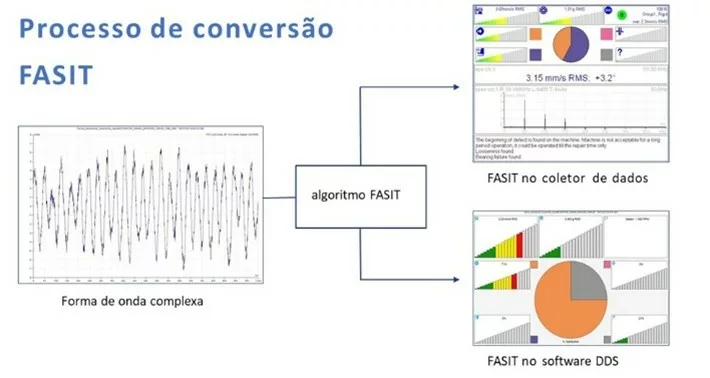

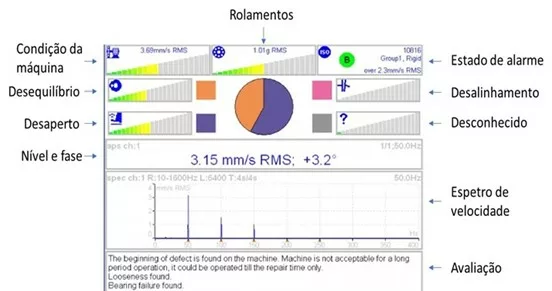

The AI system FASIT Atash works by implementing if a series of rules in signal analysis made to signs of vibrations measured in the machines.

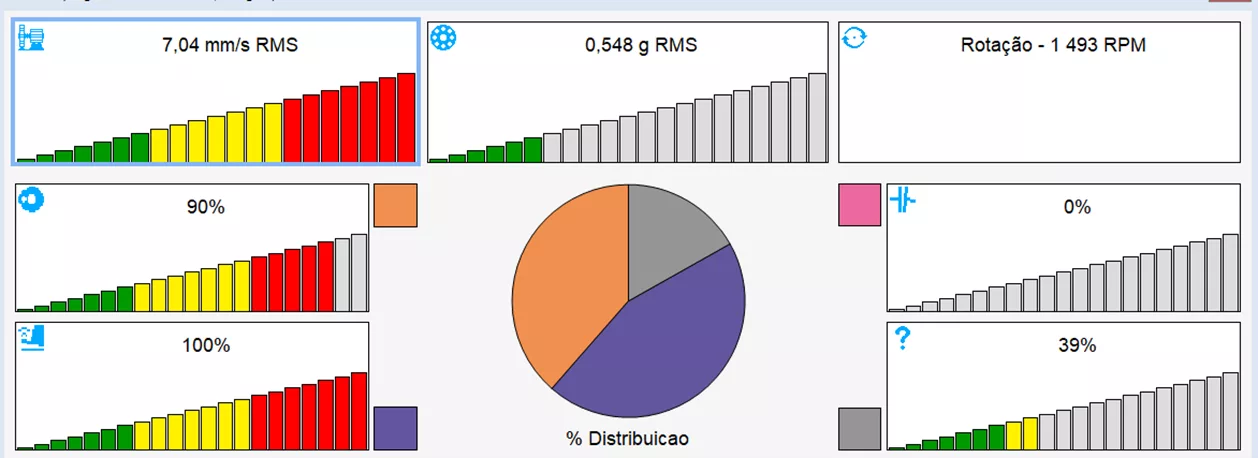

False positive and negative in Fasit – Figure 1 - How the Fasit system diagnostic rules work

From the results of this implementation the system elaborates diagnostic and issues recommendations.

False positive and negative in Fasit - Figure 2 - The presentation of the diagnosis by the AI Fasit system

The different types of malfunctions are presented in the form of icons.

False positive and negative in Fasit - Figure 3 - The different types of malfunctions are represented by icons

The examples of Vibration Analysis Diagnosis, presented below, can be done by vibration analyzers from ADASH.

False positive and negative in Fasit - Figure 4 - Anosah vibration analyzers

2 – False positive and negative

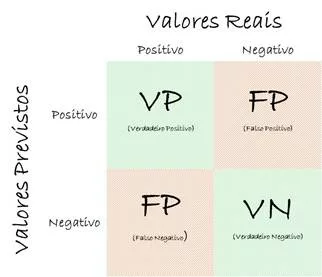

The terms “false positive” e “fake negative” are crucial metrics in the evaluation of the effectiveness of any diagnostic system, including those who use artificial intelligence for predictive maintenance. They refer to errors in the classification that can have significant consequences for operation and safety.

False positive and negative in Fasit - Figure 5 - The concept

False positive

One false positive occurs when the AI system indicates incorrectly that there is a failure on a machine, When, in reality, The equipment is in perfect working order. It is the equivalent of a false alarm.

Impact on predictive maintenance:

Although it seems harmless at first glance, a high number of false positives can have a considerable negative impact:

- Cost increase and waste: An incorrect alert can lead to unnecessary maintenance interventions, resulting in waste of time and labor. Parts that did not need to be changed can be replaced, and the production time can be lost due to non -justified stops.

- Decreased productivity: When a fake warning is triggered, The maintenance team needs to devote time and resources to verify the non -existent problem. This diverts the focus of other tasks and can impair operational efficiency.

- Distrust in the system: The recurrence of fake alarms can lead to a loss of confidence in the AI tool, causing maintenance professionals to start ignoring the alerts, even when they are legitimate.

Fake negative

One fake negative occurs when the AMA system fails to detect a failure that already exists, classifying a defective machine as being normal. The system ignores a critical problem.

False positive and negative in Fasit - Figure 6 - Diagnosis failure

Impact on predictive maintenance:

This type of error is generally considered much more dangerous than the false positive, especially for critical equipment. Consequences can be severe:

- Catastrophic failures: If the system does not warn about a real problem, The failure can evolve until it becomes catastrophic, leading to unexpected breaks, complete interruptions in production and large financial losses.3

- Safety risks: In industries where security is paramount, A false negative can lead to serious accidents, endangering workers' integrity.4

- Damage to reputation: Defective products that reach the market due to a false negative can cause significant damage to brand reputation and generate legal consequences in regulated industries.4

In short, while false positives lead mainly to the inefficiency and waste of resources, false negatives pose a greater risk, may result in financial damage, substantial operational and safety. The goal of a predictive maintenance system with AI is, therefore, maintain the rate of both errors as low as possible, with almost null tolerance for false negatives in supercritical equipment.

3 - Examples of false positive and negative

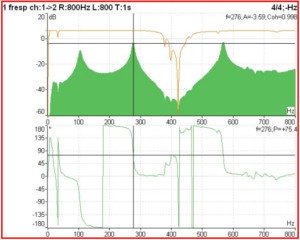

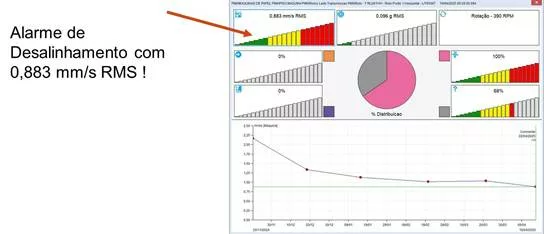

In the following figure presented can be seen an example of a false positive generated by the Fasit System system. In this case a misalignment was diagnosed in a roll of a paper machine 390 RPM, non -.

False positive and negative in Fasit - Figure 6 - Example of false positive

4 - How are the false positive and negative

It is crucial to understand that there is no fixed percentage of false positive and false negatives that can be expected of the use of AI in portable vibration analyzers. This percentage varies significantly depending on several factors.

Factors that influence the rates of false positive and false negatives:

- Quality and quantity of training data:

- High quality data: The clearer, complete and representative are the data used to train the AI model, lower the error rate. Noise data, incomplete or poorly labeled lead to less accurate models.

- Amount of data: AI models need a substantial amount of data (of vibrations of healthy machines and with diverse failures) to learn patterns effectively. Few data can result in a model that does not generalize well, increasing errors.

- AI model complexity and algorithms used:

- More sophisticated algorithms and deeper neural networks can, in theory, Capture more complex patterns and reduce errors, but they also require more data and computational power.

- The parameterization of the model is also vital. A poorly adjusted model can be overly sensitive (many false positives) or too complacent (many false negatives).

- Failure type and machine:

- Some types of failures are easier to detect by vibration than others (ex: imbalance and misalignment tend to be clearer than small internal fissures).

- Machines with more predictable and stable vibration behaviors can have lower error rates. Machines with intrinsically complex vibrations or operating under very variable conditions can be more challenging.

- Operational and environmental scenario:

- Significant variations in the machine load, velocity, temperature or even environmental conditions (external noise) can introduce “noise” in vibration data and confuse the AI model, leading.

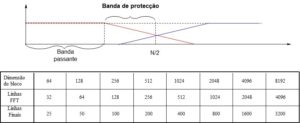

- Definition of “Normal” e “Abnormal”:

The way it defines what a vibration is “normal” and the threshold to trigger a warning “abnormality” directly influence error rates.

- False positives (FP): The system warns of a failure that does not exist.

- Causes: Excessively sensitive model, noise in the data, operating conditions not represented in training data, or an anomaly that is not really a critical failure.

- Impact: Leads to unnecessary inspections and stops, WASTING TIME AND RESOURCES.

- Fake negative (FN): The system fails to detect a real failure.

- Causes: Model not trained for that failure, too complanted model, very small or subtle failure to be detected, or low quality data that obscures the failure signal.

- Impact: Allows failures to progress, resulting in unplanned stops, greatest damage, higher repair costs and potential safety risks. In critical environments, a false negative is usually more problematic than a false positive.

- Continuous Adjustment and Optimization:

- Error rates are not static. An AI system that is monitored and continuously optimized (retreated with new data and adjusted by experts) will tend to reduce your false positive and negative over time.

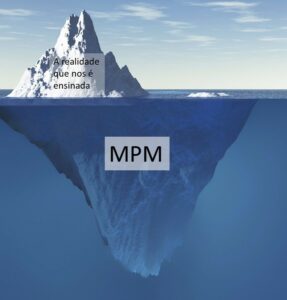

5 - The importance of realistic expectations

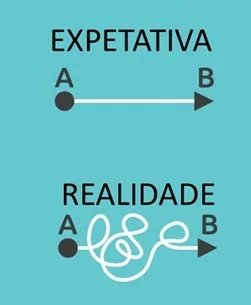

Figure 6 - expectations and reality

Instead of a specific percentage, It is more useful to think of intervals and objectives. A well -implemented AI system with appropriate predictive maintenance training data can aim above precision rates above 90-95%. However, The way this accuracy is distributed between false positive and false negatives is crucial:

- In predictive maintenance applications, The goal is to often minimize the false negatives, even if it means accepting a slightly larger number of false positive. It is preferable that the system warns of a problem that does not exist (and be verified) than failing to detect a serious problem that leads to a catastrophic failure.

- Top AI Systems, well -calibrated and in controlled environments, can reach very low false negative rates, sometimes inferior to 1-5%. The false positive rates may vary a little more, But a good system will seek to keep them at a manageable level not to overload maintenance teams.

It is essential that those who implement vibration analyzers, Understand that validation and continuous adjustment are essential for optimizing model performance and managing these error rates effectively.