Vibration case study – extraction fan

Vibration case study – extraction fan

- Gomez Gustavo Doncel, IBERDROLA GENERACIÓN SAU

- e-mail: [email protected]

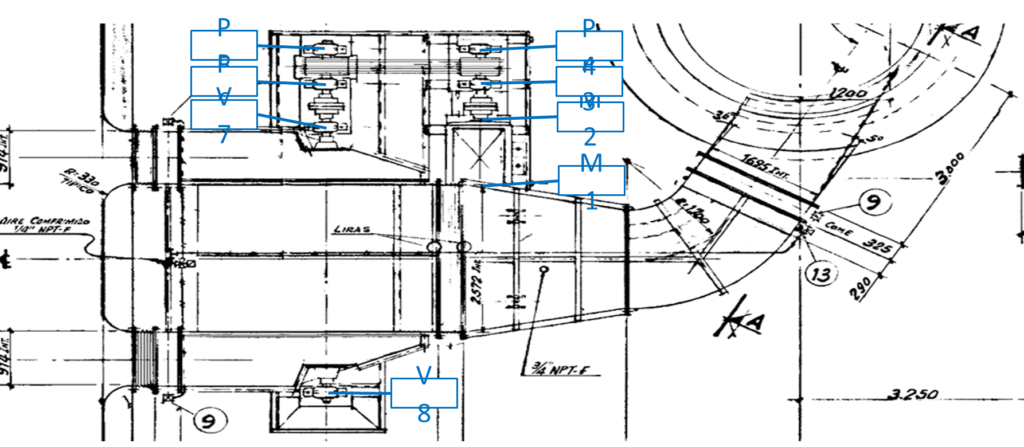

Machine features

- 450CV electric motor (985rpm)

- Centrifugal fan (780rpm)

- Pulley transmission (12 V-belts)

- 6 bearings in support

- 2 toothed couplings

- Workbench on 20 antivibratic shock absorbers

Planned maintenance

Periodic preventive maintenance:

- Lubrication and lubrication of bearings and coupling

- Revision / replacement of V-belts and pulley alignment

- Alignment and coupling check

- Engine review and tests (isolation, consumptions, broken bars, etc.)

- Inspection and cleaning of the fan

- Additionally, flow and pressure are taken

- Bi-monthly vibration predictive maintenance

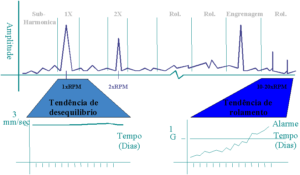

Reviewing the maintenance of the equipment in principle it seems that all the components are covered with both predictive and preventive, including cleaning of the fan impeller which over time caused the 1X vibration values of the fan to rise.

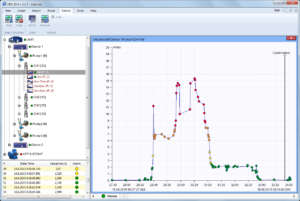

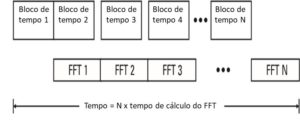

Vibrations measured with a laptop

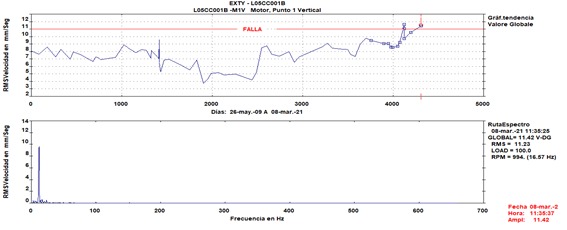

Although the reference is the ISO-10816-3 standard with periodic monitoring of vibrations every 2 months, the team's baseline was between 7 y 8mm/s, Setting our alarm at 11mm / s (Zone D of the standard).

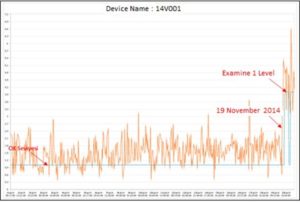

Reviewing the trends, an increase is observed in the last shots of vibrations at fan speed, mainly in the vertical, both in the fan itself and in the motor.

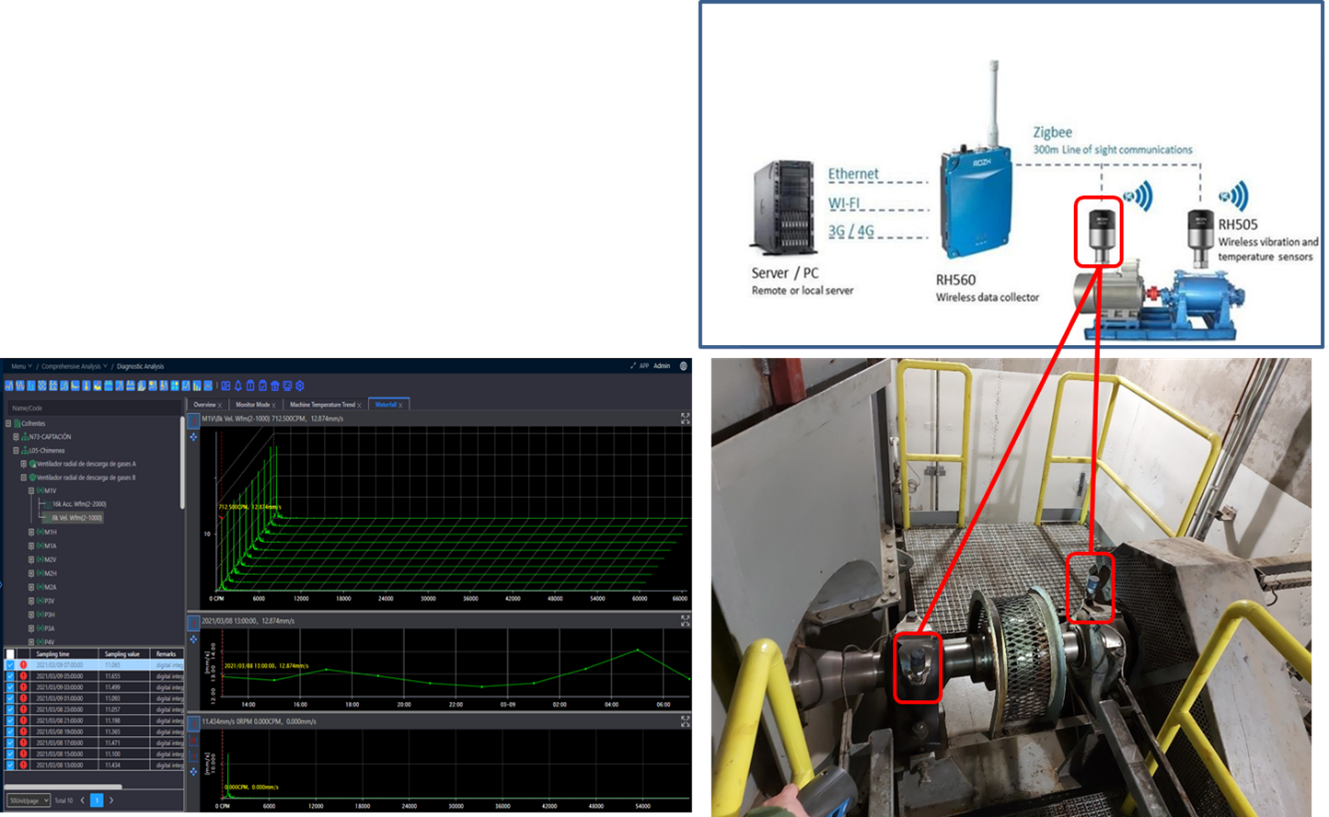

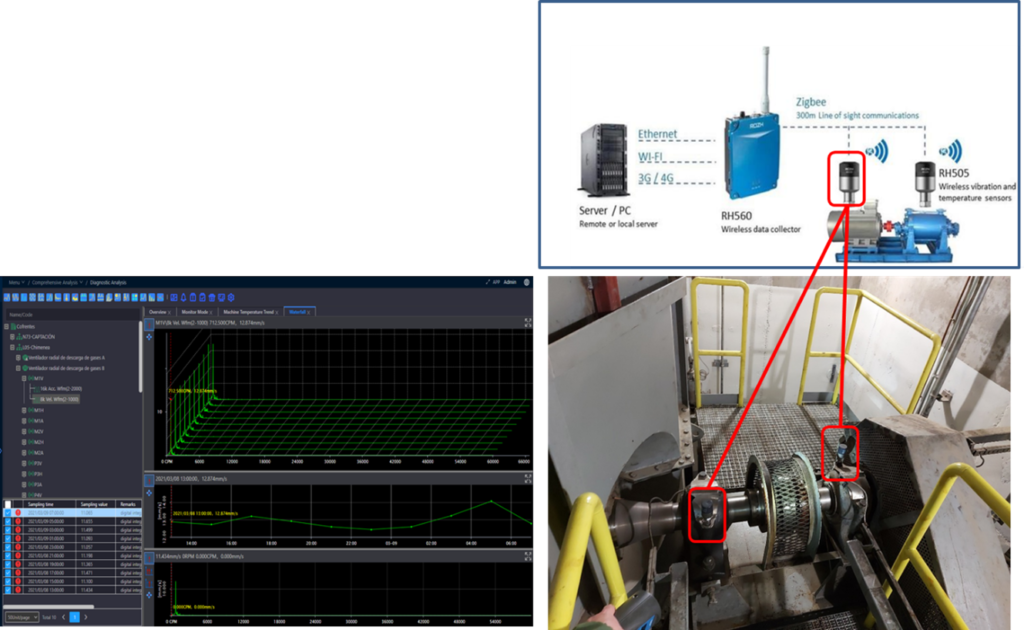

Wireless continuous measurement

To be able to correctly monitor the vibrations of the equipment continuously, it is decided to install a logger with sensores Wireless triaxial of the firma Rounds, to remotely access data in real time.

The remote system identifies that the vibrations continue to increase.

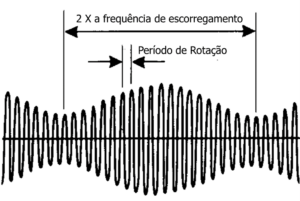

An analysis in monitor mode shows that the bench vibrates as much or more as the equipment. A clamping test of the bench is carried out with a hydraulic jack, lowering the vibration of 12 mm/s a menos de 4mm/s.

The fixation test

The bench has been temporarily fixed until the insulators are replaced, lowering the vibration to values of less than 4 mm/s.

This practical case shows us the importance of taking the bench insulators into account in preventive maintenance, since they have contributed to the amplification of the vibration by being rendered and not fulfilling their function.

To view a presentation on this topic, make click here.