Mechanical inspection – practical case in paper machine

Recovery of the production capacity of a self-adhesive paper production machine

At the end of 16 years of uninterrupted production, the productive capacity of a self-adhesive paper making machine had dropped significantly, due to quality problems. Production losses due to creases, broken paper and misalignments were very significant.

These anomalies were attributed to mechanical problems, and the collaboration of the information services was requested. mechanical inspectiona da DMC.

It was decided to dismantle the rollers of the machine and carry out an inspection of the various components.

Actions developed and what was found by mechanical inspection

The following actions were developed:

- Visual inspection;

- Warp control;

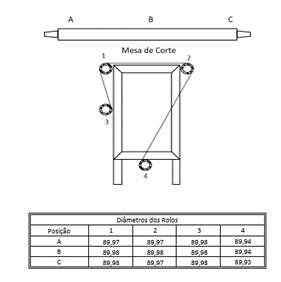

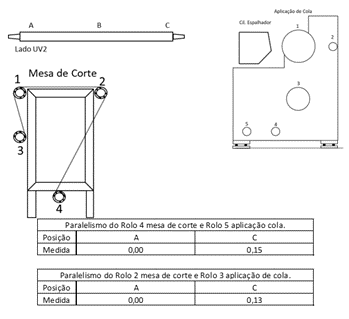

- Measuring diameters to see ovalization and wear.

Bearings have been replaced, some of the rollers were replaced with new ones and others were recovered.

When the machine was assembled, the rollers were aligned, mounted in parallel and leveling.

Results

There are no arguments against facts. At the moment, a similar intervention is being prepared, on the other machines ....