Fault detection in a bearing running at 10 RPM

Introduction

This article describes how a fault was detected in a bearing running at 10 RPM, com acoustic emission measurement. with predictive maintenancea. This bearing belonged to a bearing of a press, in a pulp mill.

industry, the machines run at very low speed are often critical to the production process and, simultaneously, large, This means that processes such as generating mechanisms of friction and impacts present, normally, a low ratio between the generated signal and the background noise.

It is this type of applications that the Emissions Measurement Acoustics (AE) and including measuring acoustic emission bearing, becomes important, by allowing in a simple way, but effective, detection of the activity produced by degradation mechanisms of a bearing even at low rotational speeds.

The measurements – breakdown in bearing to 10 RPM

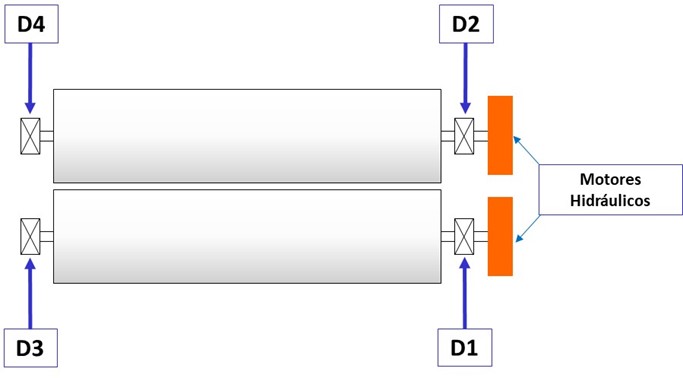

In the course of your machine inspection work, with acoustic emission measurement, within the predictive maintenance program of a pulp mill, a rise in levels was detected in a bearing.

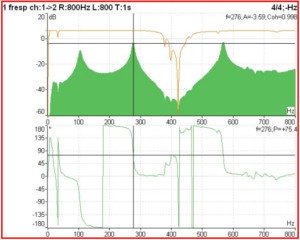

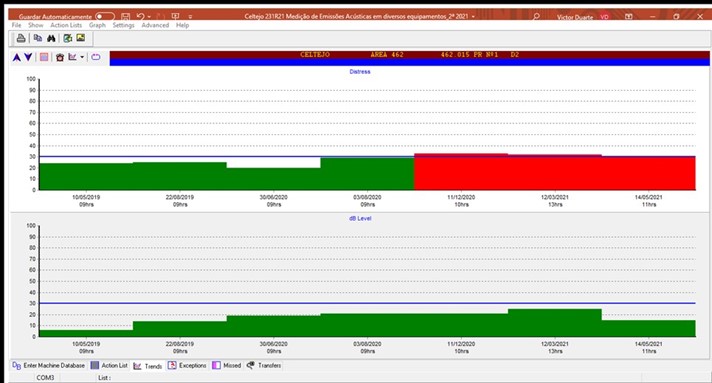

The graph shows the results of the Distress parameter and the dB parameter measured at point D2.

The analysis of the collected data reveals that the amplitude of the Distress parameter presents values slightly higher than the established limit. The dB parameter presents amplitudes below the established limit.

Auscultation of the noise emitted by the bearing revealed the presence of impacts with some significance.

recommendation made – failure in a bearing running the 10 RPM

At the conclusion of the diagnostic work it was recommended to schedule the replacement of the bearing.

In the photograph shown below you can see what was found to exist.

Conclusion

with the program predictive maintenance it was possible to avoid a prolonged stoppage, unplanned.

with measuring vibrations with Vibration Analysis common vibration analyzer with.

The investment made in the predictive maintenance services of the DMC he had, only with the detection of this malfunction, a very high return.