Experience in application of AI in a portable vibration analyzer

This article focuses on Experience in applying AI in a portable vibration analyzer.

1 - INTRODUCTION

It is expected that artificial intelligence (IA) will play a fundamental and increasingly important role in the maintenance of machines, revolutionizing the way companies manage their assets.

The use of Artificial Intelligence (IA) in portable vibration analyzers is also revolutionizing predictive maintenance and brings a number of significant benefits.

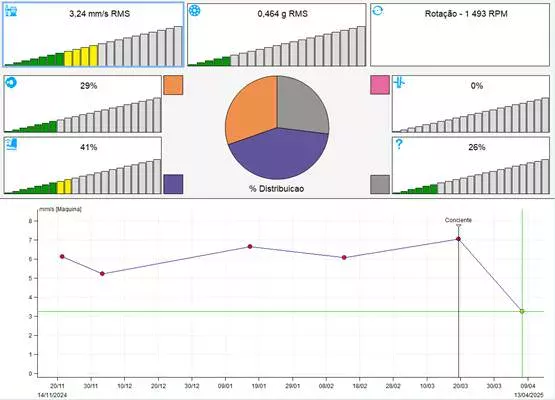

Figure 1 – Presentation of the results of the AI system, FASIT Da Adash, on a portable vibration analyzer

The question thus arose of how reliable the answers given by AI were., in real conditions, which is the central question we intend to answer and which motivated this work.

As a user of AI-enabled equipment, and intending to make the most of its use, DMC needs to answer multiple practical questions.

2 – Experience in applying AI to a portable vibration analyzer – EXPERIENCE DESIGN

It was defined that the work to be carried out to obtain unequivocal answers would be as follows:

- Formulation of the question

- Experience design

- Implementation of the experimental process

- Extraction of conclusions

3 – O sistema fasit da adash

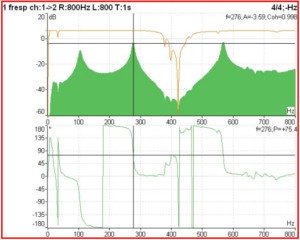

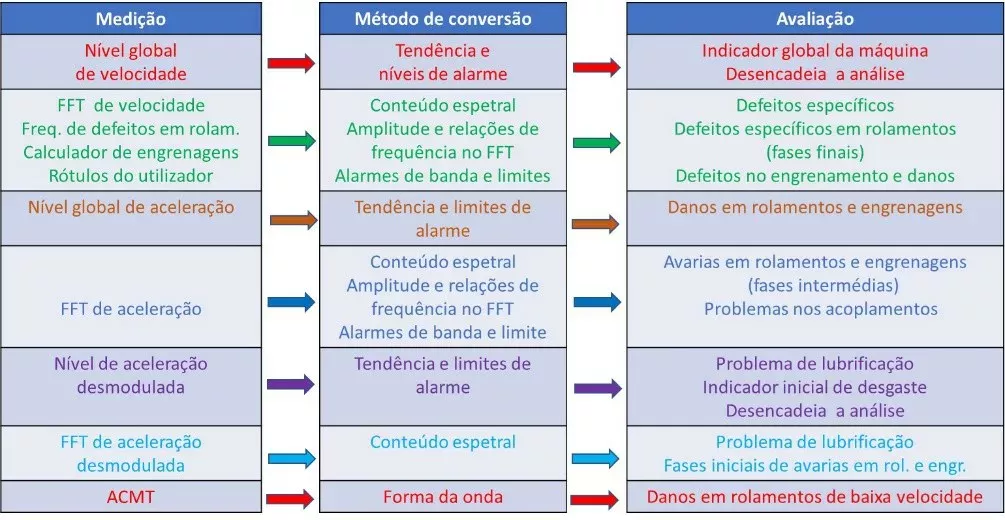

ADASH's FASIT system works through the implementation of Edge Compiting and a series of diagnostic rules in signal analysis carried out on signals measured on machines.

Figure 2 – Experience in applying AI to a portable vibration analyzer – Edge Computing and diagnostics at FASIT

From the results of this implementation the system elaborates diagnostic and issues recommendations.

Figure 3 –Experience in applying AI to a portable vibration analyzer – The process of presenting the diagnosis by the FASIT AI system

4 – EXAMPLE OF FASIT APPLICATION IN DIAGNOSIS

In this case, that is, Since its implementation has presented an alarm to the global level of vibration on the drive side on the pump. It also identified as an anomaly, imbalance and mechanical clearances. In the following figure presented can be seen the diagnosis.

Figure 4 – Experience in applying AI to a portable vibration analyzer – FASIT diagnosing pump loosening.

An inspection of the pump allowed to confirm, The existence of clearing.

In the following graph you can see the evolution of the vibration level and the FASIT after the correction has been made.

Figure 5 – Experience in applying AI to a portable vibration analyzer – FASIT and evolution of the vibration level after tightening the pump base.

5 – EXPERIENCE DESIGN

It was considered that for the results of this test to be reliable, the following conditions had to be met:

- Implementation in a real factory environment. Like this, for this purpose, a paper mill was selected;

- Implementation by inspection technicians with similar qualifications to standard industry practice, that is, Level I according to ISO 18436-2.

- A number of machines and measurements, statistically significant

.The intended responses were as follows.

- What is the percentage of false positives in FASIT diagnoses??

- How to reduce the number of false positives and false negatives?

- How important is the complexity of the machine?

- How important is it to correctly configure alarms??

6 – FASIT IMPLEMENTATION STATISTICAL DATA

6.1 First phase of implementation

In order to obtain the first results, the system was implemented in 109 machines corresponding to 417 measurement points where FASIT was implemented.

This assessment focused mainly on equipment such as pumps and fans, mostly, and also agitators, scrubbers and equipment with reducers.

The implementation result was as follows:

| Number of machines | 109 |

| Number of measurement points with FASIT | 417 |

| Number of alerts and alarms in FASIT | 23 |

| Number of correct alerts and alarms in FASIT | 19 |

| Percentage of correct alerts and alarms in FASIT | 83% |

As conclusions of the first phase, had:

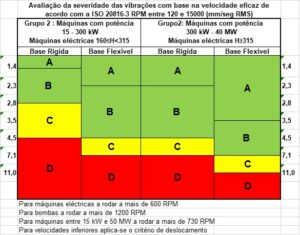

- For this sample, FASIT has a success rate of 83%.

- FASIT provides good results on equipment such as pumps and fans (above 85%).

- FASIT has difficulty providing diagnostics on systems with reducers due to, to its low output speed.

- It is imperative that equipment is classified correctly, with its well-defined alarm levels, in order to guarantee the proper functioning of FASIT.

6.2 Second phase of implementation

In the second phase of implementation, were selected 227 equipments, com 766 measurement points where FASIT was implemented,

Due to having identified themselves as difficult to apply FASIT, the following machines were removed from the study:

- Bearings with very low rotation speed, such as those in paper machine rollers;

- Intermediate and output shafts of reduction gears;

The result of the implementation of the second phase was the following:

| Number of machines | 227 |

| Number of measurement points with FASIT | 766 |

| Number of alerts and alarms in FASIT | 35 |

| Number of correct alerts and alarms in FASIT | 31 |

| Percentage of correct alerts and alarms in FASIT | 89% |

7 – FALSE POSITIVES AND FALSE NEGATIVES

It is crucial to understand that there is no fixed percentage of false positive and false negatives that can be expected of the use of AI in portable vibration analyzers. This percentage varies significantly depending on several factors.

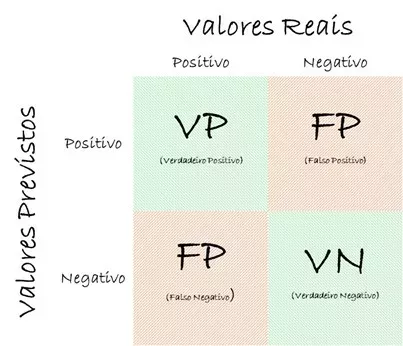

Figure 5 – False negatives and false positives

Factors that influence the rates of false positive and false negatives:

- AI model complexity and algorithms used:

- More sophisticated algorithms and deeper neural networks can, in theory, Capture more complex patterns and reduce errors, but they also require more data and computational power.

- The parameterization of the model is also vital. A poorly adjusted model can be overly sensitive (many false positives) or too complacent (many false negatives).

- Failure type and machine:

- Some types of failures are easier to detect by vibration than others (ex: imbalance and misalignment tend to be clearer than small internal fissures).

- Machines with more predictable and stable vibration behaviors can have lower error rates. Machines with intrinsically complex vibrations or operating under very variable conditions can be more challenging.

- Operational and environmental scenario:

- Significant variations in the machine load, velocity, temperature or even environmental conditions (external noise) can introduce “noise” in vibration data and confuse the AI model, leading.

- Definition of “Normal” e “Abnormal”:

The way it defines what a vibration is “normal” and the threshold to trigger a warning “abnormality” directly influence error rates.

- False positives (FP): The system warns of a failure that does not exist.

- Causes: Excessively sensitive model, noise in the data, operating conditions not represented in training data, or an anomaly that is not really a critical failure.

- Impact: Leads to unnecessary inspections and stops, WASTING TIME AND RESOURCES.

- Fake negative (FN): The system fails to detect a real failure.

- Causes: Model not trained for that failure, too complanted model, very small or subtle failure to be detected, or low quality data that obscures the failure signal.

- Impact: Allows failures to progress, resulting in unplanned stops, greatest damage, higher repair costs and potential safety risks. In critical environments, a false negative is usually more problematic than a false positive.

- Continuous Adjustment and Optimization:

- Error rates are not static. An AI system that is monitored and continuously optimized (retreated with new data and adjusted by experts) will tend to reduce your false positive and negative over time.

6 – THE IMPORTANCE OF REALISTIC EXPECTATIONS

Figure 6 - expectations and reality

Instead of a specific percentage, It is more useful to think of intervals and objectives. A well -implemented AI system with appropriate predictive maintenance training data can aim above precision rates above 90-95%. However, The way this accuracy is distributed between false positive and false negatives is crucial:

- In predictive maintenance applications, The goal is to often minimize the false negatives, even if it means accepting a slightly larger number of false positive. It is preferable that the system warns of a problem that does not exist (and be verified) than failing to detect a serious problem that leads to a catastrophic failure.

- Top AI Systems, well -calibrated and in controlled environments, can reach very low false negative rates, sometimes inferior to 1-5%. The false positive rates may vary a little more, But a good system will seek to keep them at a manageable level not to overload maintenance teams.

It is essential that those who implement vibration analyzers, Understand that validation and continuous adjustment are essential for optimizing model performance and managing these error rates effectively.

7 - CONCLUSION

The implementation of AI systems in predictive maintenance does not seek to replace experts, but the amplification of its capabilities.

By automating routine analysis and diagnosis, AI frees the vibration specialist from repetitive, data-intensive tasks, allowing it to act as a “validator” or “auditor” system suggestions.

Specific tools, like the FASIT system (Fault And Severity Indication Tool) Da Adash, utilize AI techniques with an expert knowledge base to offer diagnostic advice, acting as a valuable aid for even the most experienced professionals.

The implementation of AI in portable equipment allows its widespread use.

A DMC, with this work, intend:

- Make better use of AI technologies by your employees;

- Make a contribution to the democratization of AI application, in predictive maintenance, by Portuguese industry.