Wireless vibration measurement – resonance

Wireless vibration measurement - resonance

The systems of wireless vibration measurement on variable speed machines allow you to identify, easily, if resonance phenomena are occurring.

In an earlier article, an example of vibration measurement wireless in a steam turbine, in a generator set.

This article presents a practical case, wireless vibration measurement on a variable speed machine, where it was suspected that resonance was occurring.

Wireless vibration measurement - resonance – The situation

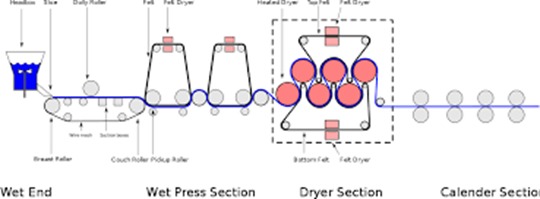

On a new variable speed machine, in this case, a paper machine, suspected the occurrence of resonance. This took place following the occurrence of excessive vibrations, in the axial direction of one of the machine's rollers.

To identify whether this was actually occurring, DMC was asked to monitor vibration, over an extended period of time.

The DMC solution for measuring wireless vibrations on a variable speed paper machine

To respond to this situation, DMC has set up a wireless vibration monitoring system at four measurement points.

De facto, there is nothing simpler to assemble than a wireless vibration measurement system. So see:

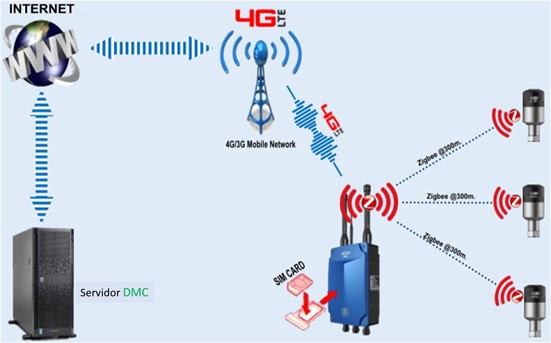

| 1) The data collector is placed where there is 3G coverage (or wireless network or Ethernet -TCPIP) and connects to 220V power; |  |

| 2) The sensors are placed at the measurement points and the power is connected to batteries; |  |

| 3) In the browser, the results of measurements on the remote server are observed, you don't need to be in the facilities where the equipment is. |  |

Like this, all together wasted an hour. Where more time was spent and what was behind and was not included, was in the computer configuration of the system. However, this is not the work of predictive maintenance technicians and maintenance managers who do not have to worry about this..

The assembled system was the one described in the diagram below.

The computer configurations were previously made at the DMC facilities so that the commissioning on site was very fast.

The sensor information collection box, was equipped with a 4G mobile phone card. Effectively, this type of communication is very easy to implement because it does not interfere with factory information technology.. Like this, the results of vibration measurements, how are specters, global waveforms and levels, all go to a DMC server.

It should be noted that this server is not at the DMC premises, but in a server park provided by a specialty firm. In this way, this type of installation is very reliable and simple.

Next you can see the wireless sensor at one of the measurement points.

Parameterization of wireless vibration measurement

For wireless vibration measurement – resonance, the system was parameterized to make the following measurements:

· Acceleration – waveform and spectrum (0-500 Hz) - each 30 minutes

· Acceleration - global value - each 1 minute

· Speed - spectrum (2-200 Hz) and overall value - each 30 minutes

The results of the measures

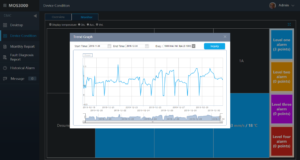

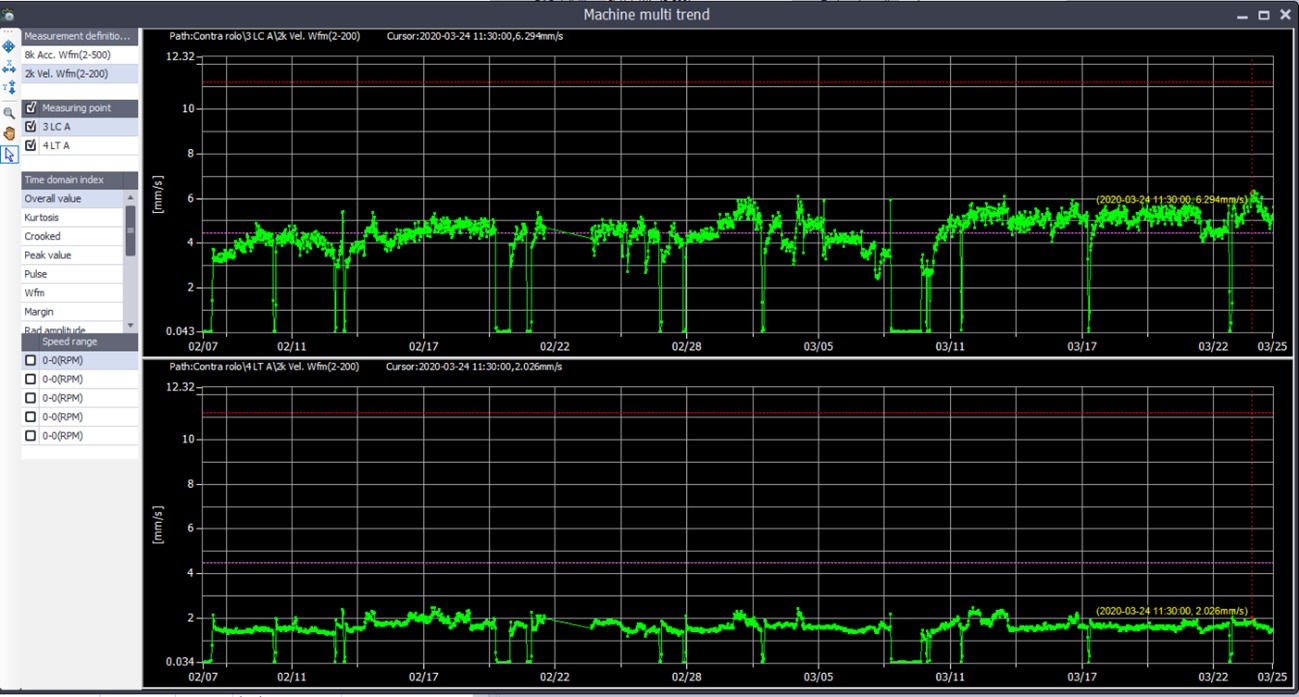

The following graphs show the results of measurements of the global level of vibrations in speed over time at two points in the axial direction..

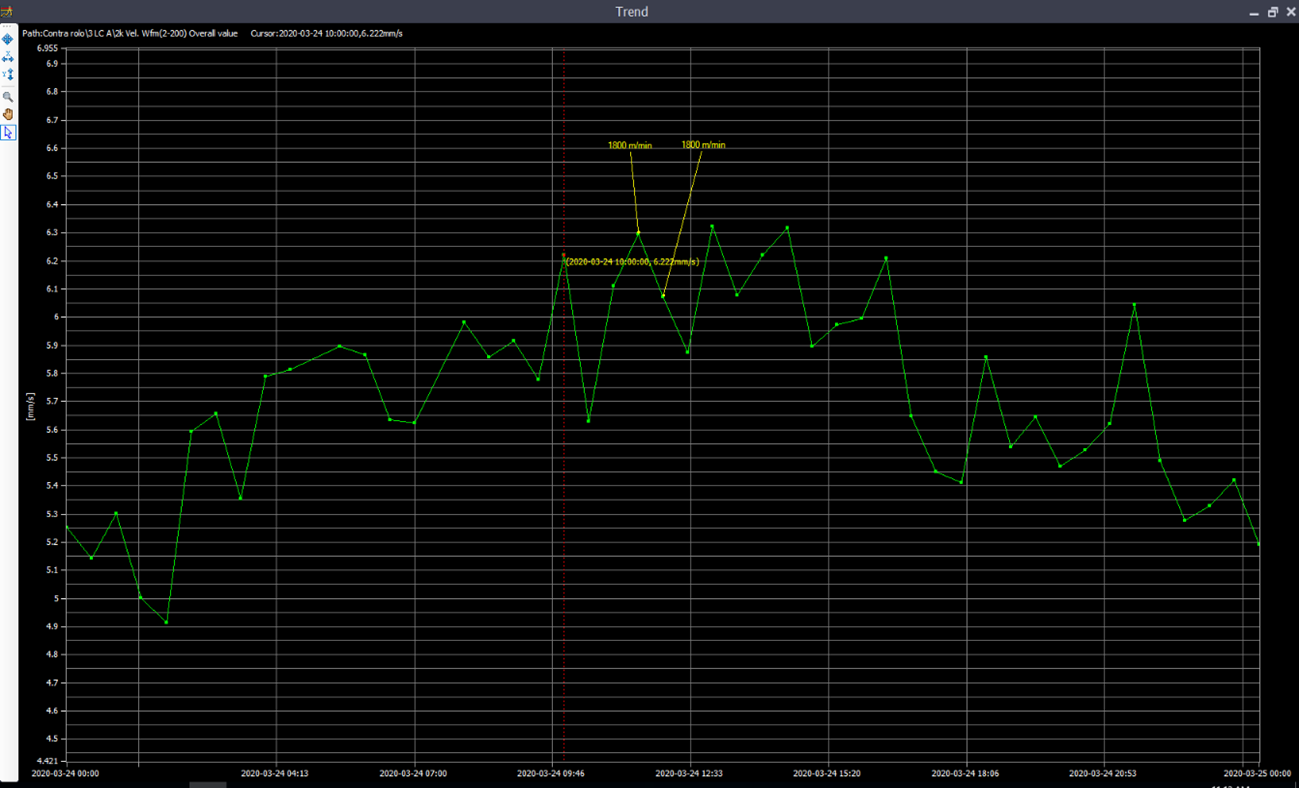

The following figure shows a detail of the previous graph, operation side, when the machine was running at 1800m / min.

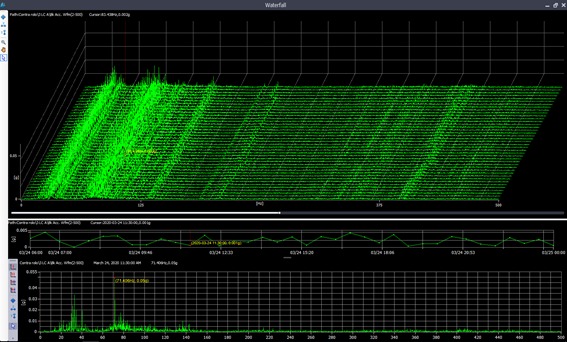

Below you can see a spectral map including the period when the machine was operating at 1800 m/min. on the Counter Roll, Driving side, accelerating. You can also see the trend and a frequency spectrum.

Some of the measured values were found to exceed those recommended by the manufacturer.

Wireless vibration measurement - resonance – The conclusion

During the measurement period, wireless vibration measurement – resonance, there were some stops and we had the opportunity to observe the machine during its normal operation and at 1800m / min.

It was found that vibrations are greater in a roller on the driving side compared to the transmission side. There was no noticeable variation in the measurement period, including the period when the machine was operating 1800 m/min.

However, it was found that some of the measured values exceeded that recommended by the manufacturer.