Protection of the world's largest gas turbine

This article describes the protection of the largest gas turbine in the world.

This article belongs to a series, which constitutes the support material for the course on vibration analysis in turbomachinery. Links to the other articles can be found on here.

Protection of the world's largest gas turbine – Introduction

The truth is that large machines are not necessarily monitored differently or with different equipment.

- May have more measurement points.

- May have more complex voting logic.

- And they can qualify for the most extensive complement of protection measurements and condition monitoring because the stakes are high in terms of lost production when they fail..

But it's basically a matter of more – not differently. The consequences of a failed or false alarm is what sets these machines apart.. Big means expensive and with big consequences.

Here we talk about the gas turbine – the most used machine in the world for air travel and which has the highest thermal efficiencies (> 60%), for energy production, when in combined cycle operation with a steam turbine.

a humble beginning

Although the first true gas turbine was patented in 1791 por John Barber de Nottinghamshire, England, would spend more than 100 years until a gas turbine capable of producing more energy than consumed was demonstrated, it's almost 150 years before one was put into operation to produce energy. Although Barber patented his invention, there is no record that he actually built the device he outlined in his patent (Figure 1).

Protection of the largest gas turbine in the world – Figure 1. Outline of Barber's invention from his patent for 1791.

De facto, if you had built it, would have quickly discovered that the project suffered from a fatal flaw: thermodynamically, there was no way to generate more energy than was consumed in their compressors, so that it was a net consumer of energy rather than a producer. Regardless, the fundamental ideas of compressing, burning and then expanding a flammable gas across the turbine blades would eventually be put into practice by a later generation of technicians..

One of these technicians was Aurel Stodola, who was heavily involved in the world's first gas turbine, used for energy production (Figure 2) – a 4MW machine that started operating in 1939, at a municipal power station in Neuchâtel, Switzerland, and that it would provide reliable backup power (emergency and peak) during the 63 next years.

Protection of the largest gas turbine in the world – Figure 2. Excerpt from Aurel Stodola's article on the world's first gas turbine in power generation service.

This machine is so important that it has been designated an International Engineering Landmark by the American Society of Mechanical Engineers. (ASME).

The article is referenced in the issue of 20 of january 1940 from Natures (a British scientific journal) and shows the machine on its test bench at the old Brown, Boveri, and Co. in a bath, Switzerland, where it was manufactured.

constant progress

From that historic machine, in 1939, power and efficiency would grow steadily over the years. 80 years to come and the technology would progress along two separate paths, but that intersect: those designed for aircraft propulsion and those intended for industrial uses. The combustion temperatures (Quadro 1) on the most advanced industrial machines would eventually become so high that exotic alloys would be needed for the vanes, produced from a single crystal and known as SX technology (single crystal).

Table 1 – Classes of gas turbines, operating temperatures and vane costs

| Class | introduction date | Temperatures | Metallurgy of vanes | Approximate cost of the first row of turbine blades |

| E | early years 70 | Up to 1200°C | Foundry | 0,5 M USD |

| F | early years 90 | Up to 1370°C | Directional solidification | 1M USD |

| G | Early 2000's | Up to 1480°C | single crystal | 2M USD |

| H | ≈2010 | Up to 1600°C | single crystal | > 2M USD |

SX technology was first used in the 1990s. 1970 pile Pratt & Whitney for its aircraft engines, like those used in the F-15 and F-16 fighters and, later, no Boeing 767 e no Airbus A310. Its first use in industrial gas turbines was in the Siemens V84.3 in 1995. At the moment, technology is regularly used in G-class machines, H and J from all manufacturers. The performance of this class of machines in simple cycle operation is superior to 40%; operating in combined cycle, exceeds the 60%.

Dimension

The power-to-weight ratio is of great importance for aircraft engines., but of lesser concern in industrial turbines. Regardless, as the power output of gas turbines increased, its size has not increased proportionately. Today's largest aviation engines produce 100 times more thrust than the first engines, but only weigh 25 times more – an improvement of 400% in power-to-weight ratio.

“…the Siemens giant has a footprint approximately equal to that of the Neuchâtel machine, but produces 150 times more power.”

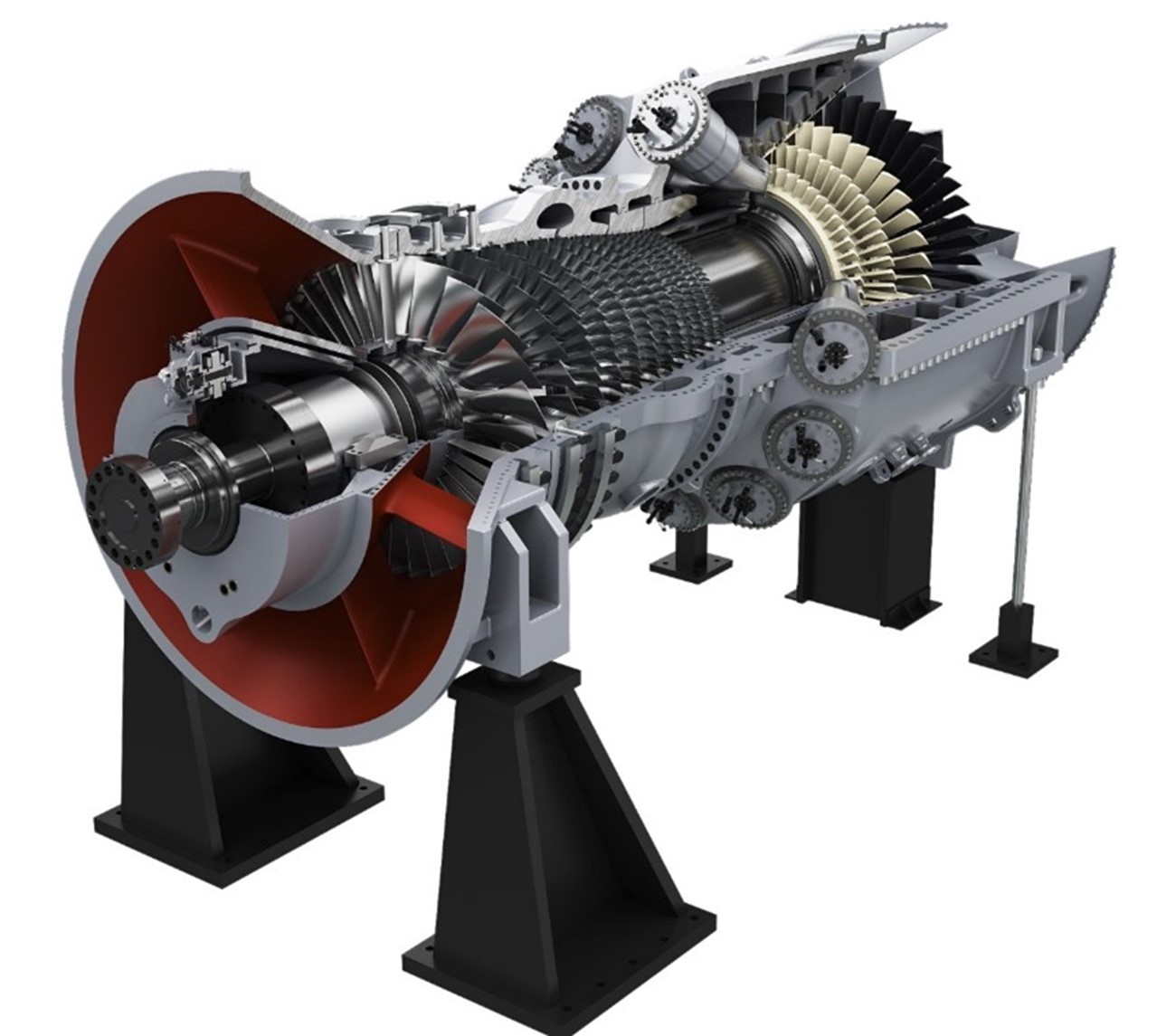

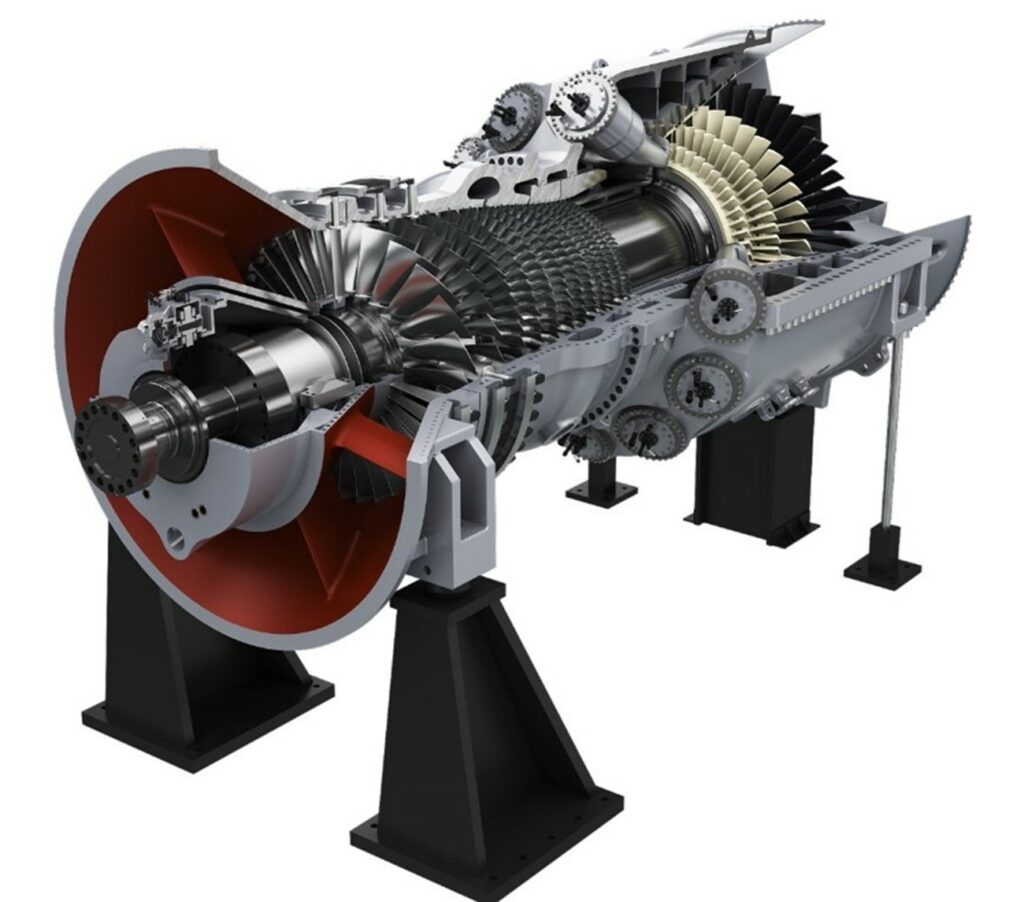

In the industrial aspect, we already talked about the 4MW unit of 1939. It had a single cycle efficiency of 17,4%, turbine inlet temperature of 550 C and it worked 3000 rpm. 80 years later, the Siemens SGT5-9000HL was born (Figure 3).

Protection of the largest gas turbine in the world – Figure 3. The SGT5-9000HL is capable of producing up to 593 MWe in simple cycle, which makes it the highest power rating of any gas turbine. she can produce 880 MWe in combined cycle operation 1:1.

It also works at 3000 rpm, but that's where the similarities end. It has a rated power of up to 593 MWe under ISO conditions, which officially makes it the most powerful gas turbine in the world at the time of writing this article.

It has a single-cycle efficiency greater than 43%. When placed in combined cycle operation 1:1, efficiency jumps to more than 64% and the output power to 880MWe. In terms of dimension, the Siemens giant has a footprint approximately equal to that of the Neuchâtel machine, but produces 150 times more energy. on the test bench, were used more than 6000 sensors monitored simultaneously to take the 9000HL machines from the design office to the market. The machine underwent the first ignition in April 2020, for the variant of 60 Hz, and the first installation of the major version of 50 Hz, at the UK's Keadby Combined Cycle Plant, underwent the first ignition, in october of 2021, and was delivered by Siemens to Keadby in mid- 2022.

| the trophy case |

Siemens is not alien to the title of “the most powerful in the world” with regard to gas turbines. At the moment, the title is stopped by the variant of 60 Hz, a SGT6-9000HL. And before that, a SGT5-8000H, launched in 2008, managed to hold three world records. The title has gone back and forth over the years and the different manufacturers and the healthy competition between them continue to push power and efficiencies ever higher.. At the moment, However, the SGT5-9000HL is poised to take top spot at Keadby Power Station, where it will be operating in a combined cycle and will have the capacity to 880 MWe.

What Meggitt monitors

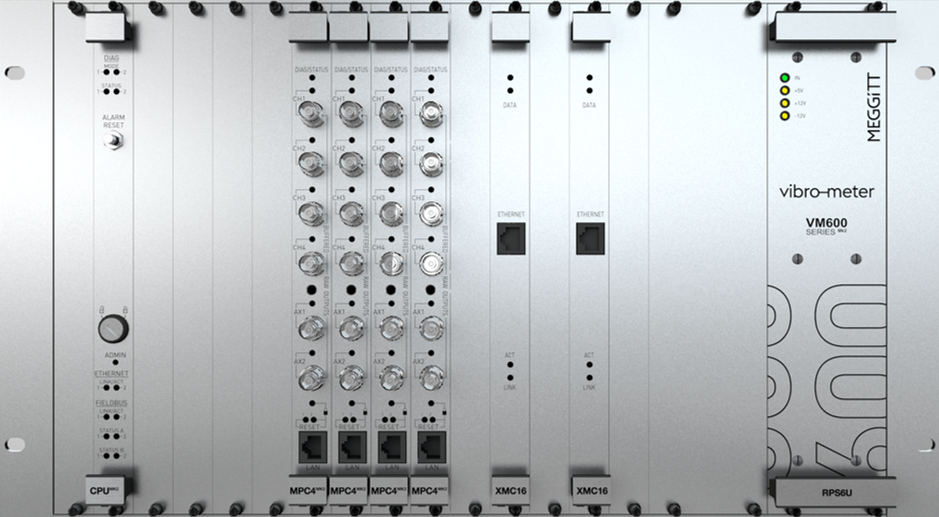

Meggitt has a long working relationship with Siemens and is the standard and preferred supplier of monitoring vibrations, together with combustion instability instrumentation in its industrial gas turbines in power generation service. The SGT-8000H family is monitored by its products and, now, a SGT-9000HL.

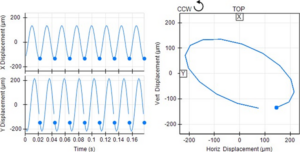

Protection of the world's largest gas turbine – Figure 5 – The VM600 monitor

As gas turbines increase in size, the basic construction remains the same. The turbine itself has only two radial bearings and one axial bearing. – like the smaller gas turbines. The generator has two radial bearings – like the smaller generators. The number of combustion chambers (can-annul technology) varies depending on engine size and engine variant. 50 Hz or 60 Hz. When placed in combined cycle configurations, steam turbines are also not very different in terms of instrumentation. What changes, evidently, is the amount of energy produced by the gas turbine and any associated steam turbines, if you use the exhaust gases to produce steam. A false trip or a misfire means that enormous amounts of energy are involved., maybe greater than 800MWe.

Meggitt is very proud that Siemens has relied on its solutions for many years across its range of gas and steam turbines., and that trust continues to your highest bidder: the SGT-9000HL family.

Protection of the world's largest gas turbine – resume

After 70 years, Meggitta has learned the many nuances of protecting machines and monitoring their condition. And although it monitors thousands of machines worldwide, collectively encompassing TW of power, there's still a special meaning to being in charge of the world's most powerful gas turbine.

Here you can see an article about the protection of the largest steam generator set in the world.